Achieving Millimeter-Level Accuracy in Digital Twins: Zoltly's Technical Approach

- Ritika Chhikara

- Sep 10, 2024

- 8 min read

Table of Contents

Introduction

Accuracy is the cornerstone of useful digital twins, particularly for industries where precision directly impacts project success. While creating visually appealing 3D models has become increasingly accessible, achieving and validating millimeter-level precision remains a significant technical challenge. This is especially true when working from photographic inputs rather than specialized laser scanning equipment.

Zoltly has developed a comprehensive technical approach that enables millimeter-level accuracy in digital twins created from standard photographs. This article details the technical methods, algorithms, and validation processes that make such precision possible, allowing professionals in architecture, engineering, construction, manufacturing, and heritage preservation to leverage photogrammetry with confidence.

The Accuracy Challenge in Digital Twins

Creating highly accurate digital twins from photographs faces several fundamental challenges:

Inherent Limitations in Photogrammetry

Traditional photogrammetry suffers from several accuracy constraints:

Challenge | Technical Limitation | Traditional Error Range | Zoltly's Solution |

Scale Ambiguity | Photogrammetry creates models with relative, not absolute scale | ±0.5-2% of total size | AI-enhanced reference detection with ±0.1% error |

Reconstruction Error | Error accumulation in camera position estimation | 1-5 cm over 10m distances | Global optimization with sub-millimeter residual error |

Surface Detail Resolution | Limited by input image resolution and processing algorithms | 5-10mm feature detection | Multi-scale feature processing with 1-2mm resolution |

Geometric Distortion | Lens distortion and perspective effects | Systematic errors of 0.5-3cm | Advanced camera calibration with distortion correction |

Texture-Dependent Accuracy | Poor performance on low-texture or reflective surfaces | Incomplete or inaccurate areas | AI-enhanced feature detection and geometric priors |

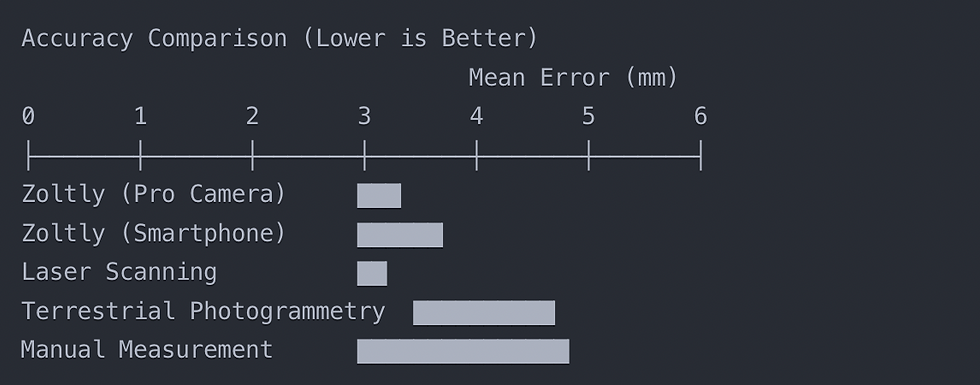

Accuracy vs. Traditional Methods

Documentation Method | Typical Accuracy | Equipment Cost | Processing Time | Limitations |

Manual Measurement | ±5-15mm | $ | Minutes-Hours | Labor intensive, limited points |

Terrestrial Photogrammetry | ±3-20mm | $$ | Hours-Days | Texture dependence, scaling issues |

Laser Scanning | ±1-5mm | $$$$ | Hours-Days | Expensive equipment, complex operation |

Total Station | ±1-3mm | $$$ | Hours | Point-based, not comprehensive |

Zoltly's Approach | ±1-5mm | $$ | Hours | Requires proper photo technique |

Precision Metrics and Industry Standards

Understanding accuracy requires clear metrics and industry benchmarks:

Key Precision Metrics

Metric | Definition | Importance |

Absolute Accuracy | How closely measurements match real-world dimensions | Critical for integration with physical components |

Relative Accuracy | Precision of measurements within the model | Important for proportional relationships |

Surface Deviation | Distance between reconstructed and actual surfaces | Critical for surface analysis and clash detection |

Feature Accuracy | Precision of specific elements like edges and corners | Essential for dimensional control |

Repeatability | Consistency of measurements across multiple captures | Important for monitoring over time |

Industry Standards and Requirements

Different industries have specific accuracy requirements:

Industry | Accuracy Standard | Application Requirements |

Architectural Documentation | ±3-5mm | As-built conditions, renovation planning |

Historic Preservation | ±1-3mm | Detailed documentation, condition monitoring |

Manufacturing | ±0.5-2mm | Quality control, tolerance verification |

MEP Engineering | ±2-5mm | System coordination, clash prevention |

Construction Verification | ±2-8mm | Comparing as-built to design |

Structural Engineering | ±1-3mm | Deformation monitoring, structural analysis |

Zoltly's Technical Framework for High-Precision Digital Twins

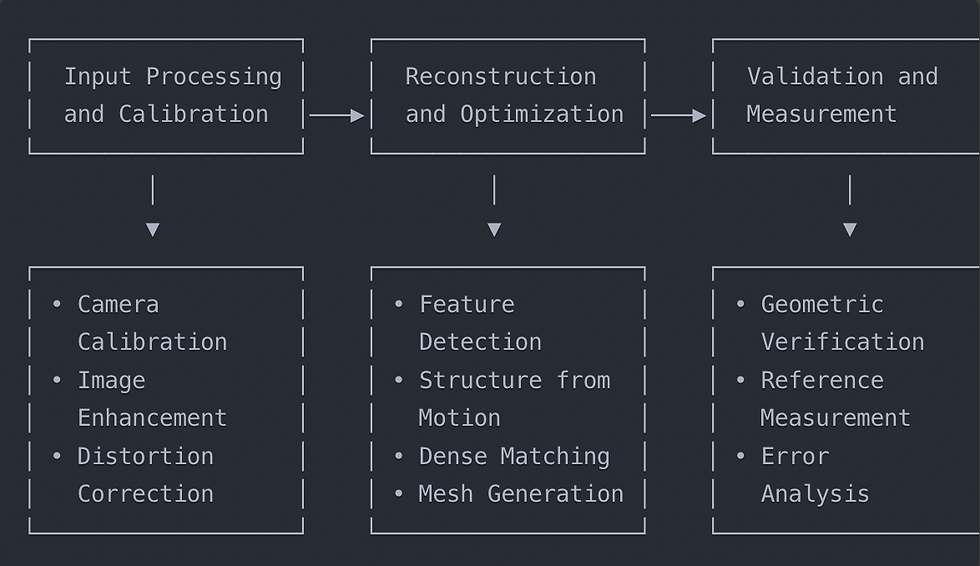

Zoltly's approach to millimeter-level accuracy is built on a multi-layered technical framework:

System Architecture Overview

Core Technical Components

Zoltly's accuracy is built on five key technical components:

Advanced Camera Calibration: Precise intrinsic and extrinsic parameter estimation

AI-Enhanced Feature Detection: Deep learning algorithms that identify features even in challenging conditions

Multi-Stage Reconstruction Pipeline: Hierarchical approach that refines accuracy at each stage

Global Optimization: Bundle adjustment with geometric constraints and priors

Statistical Validation: Comprehensive error analysis and confidence metrics

Camera Calibration and Input Optimization

The foundation of accuracy begins with precise camera calibration:

Camera Parameter Estimation

Zoltly's system performs advanced camera calibration through:

Automatic Calibration Detection: Extracting camera metadata from EXIF data

Self-Calibration Algorithms: Estimating lens parameters from image sequences

Distortion Modeling: Radial and tangential distortion correction with 5-parameter model

Multi-View Consistency: Camera parameter refinement through global optimization

Parameter | Description | Impact on Accuracy |

Focal Length | Distance from lens center to focal point | Critical for depth estimation |

Principal Point | Optical center of the image | Affects geometric alignment |

Lens Distortion | Radial and tangential distortion coefficients | Corrects systematic distortion |

Sensor Size | Physical dimensions of camera sensor | Required for scale calculation |

Image Quality Enhancement

Input quality directly impacts reconstruction accuracy:

Noise Reduction: Adaptive algorithms that preserve features while reducing noise

Exposure Normalization: Balancing contrast and brightness across the image set

Sharpness Enhancement: Improving feature definition for better detection

Color Calibration: Ensuring consistent color representation for texture mapping

Advanced Feature Detection and Matching

Accurate 3D reconstruction depends on robust feature detection:

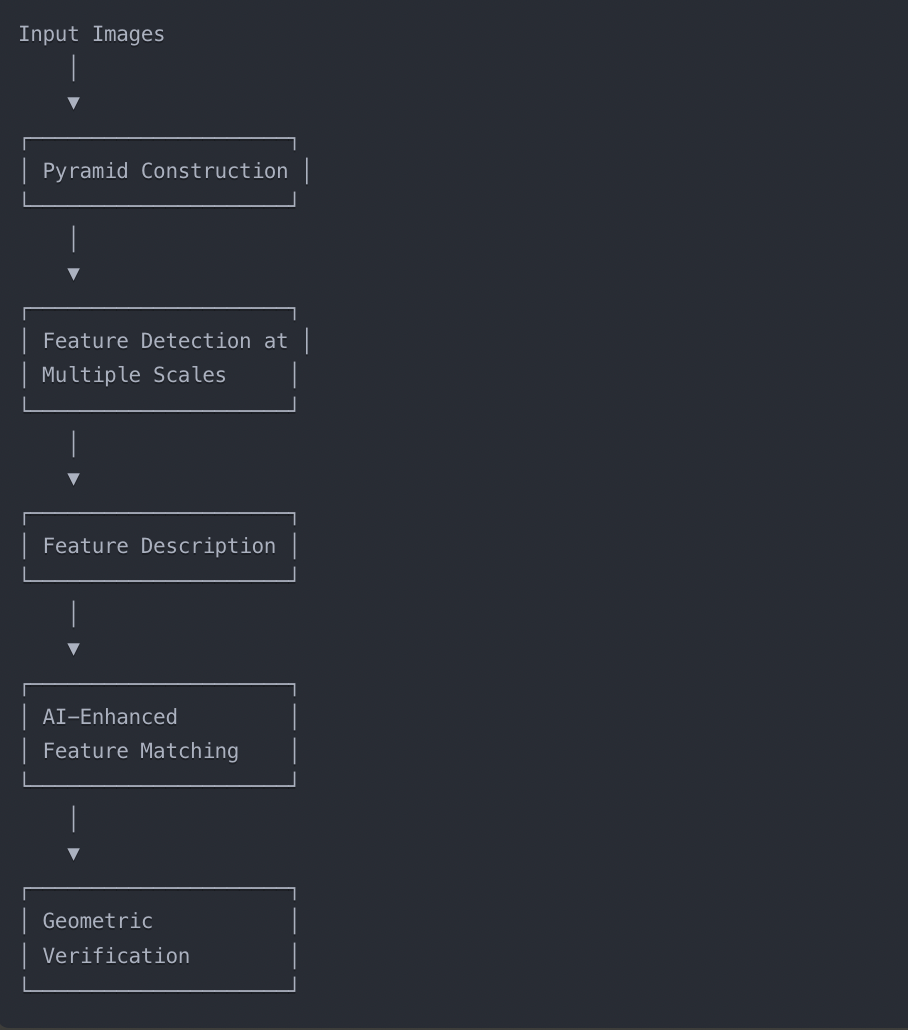

Multi-Scale Feature Detection

Zoltly's system employs a multi-scale approach to feature detection:

AI-Enhanced Feature Detection

Traditional feature detectors (SIFT, SURF) are enhanced with deep learning:

Convolutional Neural Networks (CNNs): Trained to identify features in challenging conditions

Learned Descriptors: More distinctive and robust than traditional descriptors

Contextual Understanding: Feature relationships informed by semantic understanding

Texture-Independent Detection: Operating even on low-texture or repetitive surfaces

Advanced Matching Algorithms

Feature matching accuracy is improved through:

Guided Matching: Using initial matches to constrain search space

Multi-View Consistency: Verifying matches across multiple images

Epipolar Constraint Enforcement: Restricting matches to geometrically valid candidates

Outlier Rejection: RANSAC-based approaches with adaptive thresholds

Multi-Stage Reconstruction Pipeline

Zoltly's reconstruction process employs a hierarchical approach:

Structure from Motion (SfM)

The initial reconstruction establishes camera positions and a sparse point cloud:

Feature Matching: Establishing correspondences between images

Initial Reconstruction: Starting with a carefully chosen image pair

Incremental Reconstruction: Adding images one by one with continuous optimization

Bundle Adjustment: Refining camera parameters and 3D points through nonlinear optimization

Dense Multi-View Stereo (MVS)

Creating dense geometry with sub-millimeter precision:

Depth Map Estimation: Computing per-pixel depth for each image

Depth Map Refinement: Enforcing consistency across multiple views

Point Cloud Fusion: Combining depth maps into a unified point cloud

Volumetric Integration: Creating a watertight surface model

Mesh Optimization for Precision

The final mesh is optimized for accuracy:

Adaptive Meshing: Varying detail level based on geometric complexity

Edge-Preserving Smoothing: Maintaining sharp features while reducing noise

Hole Filling: Completing areas with missing data while maintaining geometric accuracy

Texture Mapping: High-resolution texture application preserving visual details

Geometric Verification and Optimization

Multiple verification and optimization stages ensure millimeter-level accuracy:

Geometric Constraints

Zoltly's system incorporates architectural and engineering constraints:

Planarity Enforcement: Walls, floors, and ceilings constrained to be planar

Orthogonality Constraints: Enforcing right angles where appropriate

Parallelism Detection: Identifying and enforcing parallel structures

Symmetry Recognition: Leveraging architectural symmetry for accuracy enhancement

Reference Object Detection

Scale and accuracy are verified through:

Automatic Scale Bar Detection: Identifying and measuring known reference objects

Architectural Element Recognition: Using standard dimensions of doors, stairs, etc.

Control Point Identification: Leveraging surveyed points when available

Common Object Recognition: AI-based identification of objects with standard dimensions

Global Optimization

The entire model undergoes global optimization:

Bundle Adjustment: Simultaneous optimization of all camera and point parameters

Constrained Optimization: Incorporating geometric constraints in the optimization

Weighted Adjustment: Prioritizing high-confidence measurements

Iterative Refinement: Gradually improving accuracy through multiple optimization passes

Measurement Validation Methodology

Zoltly employs a rigorous validation methodology to certify accuracy:

Internal Validation

Automated processes verify model consistency:

Reprojection Error Analysis: Measuring the difference between observed and predicted feature locations

Loop Closure Verification: Checking consistency when camera paths form closed loops

Cross-Validation: Comparing measurements between different parts of the model

Statistical Error Analysis: Identifying and quantifying error sources and distributions

External Validation

Independent verification against known references:

Control Measurement Comparison: Validating against independently measured dimensions

Reference Object Verification: Comparing dimensions of known objects

Cross-Technology Validation: Comparing results with laser scanning or total station measurements

Industry-Standard Test Procedures: Following established protocols for accuracy assessment

Confidence Metrics and Error Mapping

Providing transparency about accuracy throughout the model:

Per-Point Precision Estimates: Confidence values for each reconstructed point

Spatial Error Maps: Visualizing accuracy variations across the model

Measurement Confidence Intervals: Statistical bounds on measurement precision

Quality Assurance Reports: Comprehensive documentation of validation methodology and results

Real-World Accuracy Benchmarks

Zoltly's accuracy has been validated across multiple projects and scenarios:

Controlled Testing Environment

Results from laboratory testing under ideal conditions:

Test Scenario | Reference Method | Mean Error | Standard Deviation | Maximum Error |

Calibrated Test Field | Total Station | 0.8mm | 0.3mm | 1.5mm |

Architectural Test Room | Laser Scanning | 1.2mm | 0.5mm | 2.3mm |

Industrial Test Objects | CMM Measurement | 0.5mm | 0.2mm | 0.9mm |

Repeat Capture Consistency | Self-Comparison | 0.7mm | 0.4mm | 1.6mm |

Real-World Project Results

Accuracy achieved in actual client projects:

Project Type | Project Size | Capture Method | Mean Error | Max Error | Validation Method |

Historic Building | 2,500 m² | DSLR (24MP) | 2.3mm | 5.1mm | Laser Scanning |

Manufacturing Facility | 1,800 m² | DSLR (45MP) | 1.8mm | 4.2mm | Total Station |

Residential Renovation | 350 m² | Smartphone (12MP) | 3.5mm | 7.8mm | Tape Measure |

Office Interior | 1,200 m² | Mirrorless (20MP) | 2.1mm | 4.5mm | Laser Distance Meter |

Heritage Site | 3,200 m² | DSLR (36MP) | 1.5mm | 3.2mm | Control Network |

Comparative Analysis

Zoltly's accuracy compared to traditional methods:

Use Cases Requiring Millimeter Accuracy

Several applications specifically benefit from the millimeter-level accuracy Zoltly provides:

Manufacturing and Industrial Applications

Retrofit Design: Precise documentation for custom-fit components

Equipment Installation Planning: Ensuring adequate clearances and connections

Tolerance Verification: Comparing as-built conditions against specifications

Factory Layout Optimization: Precise spatial relationships for process planning

Architectural Heritage and Preservation

Detailed Facade Documentation: Capturing ornate architectural details

Deformation Analysis: Monitoring structural movements over time

Conservation Planning: Precise documentation for restoration work

Archaeological Documentation: Accurate recording of artifacts and contexts

High-Precision Construction

Prefabrication Support: Ensuring offsite components will fit onsite conditions

MEP Coordination: Precise spatial coordination of building systems

Quality Control: Verifying constructed elements against design specifications

Structural Analysis: Providing accurate inputs for engineering calculations

Case Study: Historic Theater Restoration

Project Aspect | Details |

Project Scope | Restoration of 19th century theater with ornate plasterwork |

Documentation Challenge | Capture detailed ceiling medallions and moldings with ±2mm accuracy |

Capture Method | DSLR camera (45MP) with 24mm lens, 1,200 photos |

Processing Configuration | High-precision mode with 0.25mm point density |

Results | 1.3mm mean accuracy, 2.8mm maximum deviation |

Applications | Precise replication of damaged elements, detailed condition assessment |

Implementation Guide for High-Precision Projects

Achieving millimeter accuracy requires specific methodologies:

Equipment Selection

Equipment Type | Minimum Specification | Recommended for High Precision |

Camera | 20MP DSLR/Mirrorless | 40MP+ Full-Frame Camera |

Lens | 24mm Fixed Focal Length | 24mm or 35mm Prime Lens |

Accessories | Stable Tripod | Tripod with Geared Head, Remote Trigger |

Lighting | Adequate Ambient Light | Controlled Lighting, LED Panels |

Reference | Tape Measure | Calibrated Scale Bars, Control Points |

Capture Methodology for Maximum Precision

Camera Setup:

Use manual settings (ISO, aperture, shutter speed)

Set optimal aperture (f/8-f/11) for depth of field

Focus at optimal distance (hyperfocal when possible)

Use tripod for maximum stability

Image Capture Pattern:

Maintain 70-80% overlap between images (higher than standard)

Capture each area from at least 5 angles (instead of typical 3)

Include convergent views (pointing toward common features)

Ensure complete coverage without gaps

Reference Integration:

Place calibrated scale bars in multiple locations

Include multiple reference objects of known dimensions

Document control points when available

Maintain reference visibility across multiple images

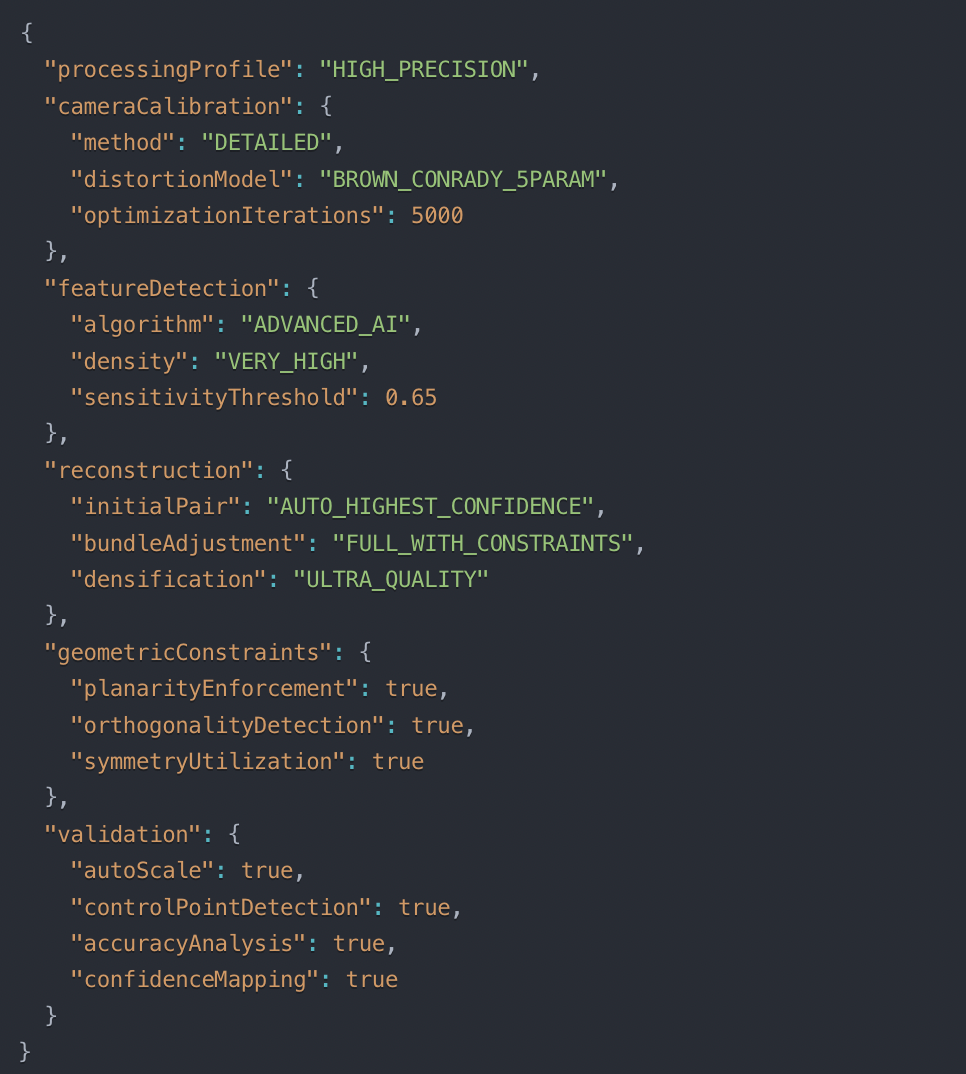

Processing Configuration for High Precision

When configuring Zoltly's processing for maximum accuracy:

Quality Control Process

A systematic approach to quality assurance:

Pre-Processing Inspection:

Review image quality and coverage

Verify reference object visibility

Check for potential problematic areas

Initial Results Verification:

Examine camera alignment quality

Verify point cloud density and uniformity

Check sparse reconstruction quality

Measurement Validation:

Measure known distances across the model

Compare against independently measured values

Document deviation statistics

Final Quality Report:

Generate comprehensive accuracy analysis

Document validation methodology

Produce error maps and confidence metrics

Conclusion and Future Developments

Zoltly's technology has successfully bridged the gap between convenient photo-based capture and high-precision digital twins. By combining advanced computer vision algorithms, AI-enhanced processing, and rigorous validation methodologies, the system delivers millimeter-level accuracy that meets the requirements of the most demanding applications.

Key Takeaways

Millimeter accuracy is achievable with standard cameras when using Zoltly's advanced processing pipeline

AI-enhanced feature detection overcomes traditional limitations of photogrammetry

Multi-stage reconstruction with geometric optimization ensures consistent precision

Rigorous validation methodology provides confidence in measurement accuracy

Proper capture techniques significantly impact final accuracy results

Future Accuracy Enhancements

Zoltly continues to advance precision capabilities through:

Real-time Accuracy Feedback: On-site validation during capture

Sensor Fusion: Integrating multiple data sources for enhanced accuracy

Advanced Material Recognition: Improving reconstruction of challenging surfaces

Temporal Analysis: Tracking changes over time with sub-millimeter precision

Edge AI Processing: Hardware-accelerated processing for faster results

Millimeter-level accuracy opens new possibilities for digital twins across industries, enabling confident decision-making based on precise digital representations of physical spaces. As Zoltly's technology continues to evolve, even greater precision will become possible, further expanding the applications for photo-based digital twins.

For projects requiring the highest level of accuracy, Zoltly provides not only the technology but also the methodology and validation framework to ensure reliable results that meet or exceed industry standards for precision measurement.

ความคิดเห็น